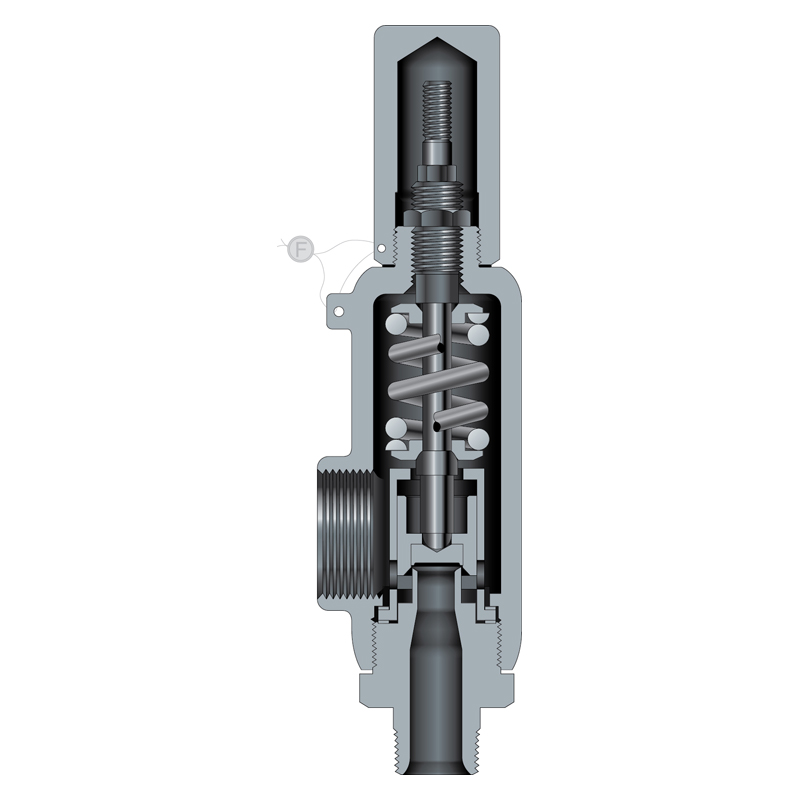

2700 Series - Process Valve - Pressure Relief Valve

Farris

Designed to provide customers with the widest selection of sizes, orifices, and construction materials, the Series 2700 meets the exact demands of the process industry.

The 2700 Series pressure relief valve, also known as an expansion relief valve, features a superior design that handles air, steam, vapor, and liquid services. In addition, the fixed blowdown design simplifies testing and repair, and the maximum interchangeability of parts allows for easy maintenance.

FEATURES & BENEFITS:

- Metal Seat with optional o-ring

- Balanced design option

- Flanged option

- Optional welding nipple and sanitary connections