Overview

General

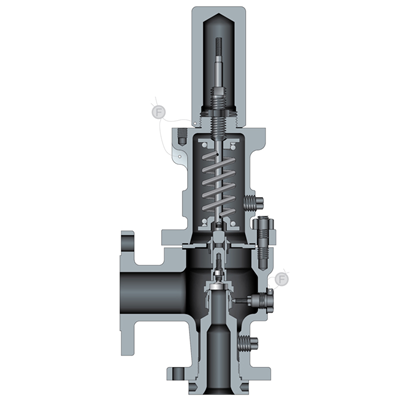

2600 Series & 2600L Series - Process Valve

Certifications

- ASME/NB Section VIII and III for Air, Steam and Water

- CSA B51 (Canada CRN)

- ISO 9001- 2008

- PED 97/23/EC (European Pressure Equipment Directive)

- ATEX 94/9/EC (European Potentially Explosive Atmospheres)

- CSQL (China)

- GOST-R (Russian)

- US Coast Guard

- Nuclear – 10 CRF 50 Appendix B, NCA-4000, NQA-1 N285.0

- First Point Assessment Limited

PRESSURE RELIEF VALVE - DESIGN & OPERATION

Farris’s pressure relief valves are designed to automatically protect your equipment against excessive overpressure. The Series 2600 pressure relief valves are designed to function equally well on air, gases, steam, or liquid service.

The pressure relief valve design incorporates several features which allow this valve to take a maximum amount of piping strain without hampering the functional characteristics of the valve or contributing to serious leakage.

STRENGTH & TIGHTNESS

The superior strength built into the body of the Farris pressure relief valve to resist these discharge piping strains materially reduces the deflection and distortion in the valve and reduces the leakage encountered, when at times, discharge piping strains become excessive.

The valve is engineered for exceptional tightness because of positive alignment, a high strength disc design, the elimination of thermal distortion and

optimum seating surface finish.

NOZZLE DESIGN

The Farris full nozzle pressure relief valve design incorporates a nozzle shape to provide:

- A high stable flow coefficient.

- Greater strength to resist possible discharge piping strains.

- Wrenching provisions on raised face nozzles where they will not interfere with the flow path.

The superior design allows easy maintenance by simplifying nozzle removal and assembly.