Utilizing the latest computer aided design systems and software Solent & Pratt enables special design requirements, dimensions and specifications to be accommodated. The TOSV™ series valves are of dedicated Triple Offset * geometry design. This particular feature eliminates the disc-to-seat rubbing condition, normally associated with 'HPBV' butterfly valves, which induces wear of varying degrees, even in metal seated versions. This is an ideal replacement valve for Ball, Plug or Gate types

Standard TOSV design features include zero leakage with bi-directional shut off to API 598, a field replaceable seat and seal ring for reduced maintenance costs, non-galling design to enable a wide variety of material options, with options for live loaded packing and arduous duty bearing protectors.

Solent & Pratt utilizes the latest computer aided design systems and software enabling special design requirements, dimensions and specification to be accommodated. Valves are built and tested to the following standards:

Solent & Pratt utilizes the latest computer aided design systems and software enabling special design requirements, dimensions and specification to be accommodated. Valves are built and tested to the following standards:

Material Range

Valve design range is available in most other materials

Patented Two direction valve geometry

Patented Two direction valve geometry

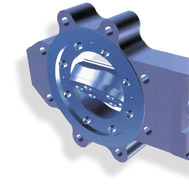

The Solent & Pratt Triple Offset Segment Valve utilizes the well established valve geometry where the shaft is offset from the body in two directions (1) and (2), whilst the disc is a segment taken from a cone where the apex is offset from the center line of the valve (3). The disc (segment) of the valve houses a field replaceable metal laminate seal whilst the field replaceable seat ring is housed in the body of the valve.

Due to the valve geometry there is no interference or rubbing between seat and seal as the valve strokes through it’s full 90°.

| Features and Benefits | |

|---|---|

| Feature | Description |

| Replaceable seat and seal | Triple Offset Geometry with field replaceable seat and seal rings |

| Zero leakage | Bi-directional shut-off to API 598, zero leakage capability |

| Resilient metal seat | Torque generated resilient metal sealing provides repeatable long term sealing performance |

| Firesafe | The valve design range is certified Firesafe to NS EN ISO 10497, BS 6755 : Part 2 and API 6FA : API 607 4th edition |

| Steam Jacket | Integral steam jackets are available on the double flanged body design |

| Face-to-face | API 609, BS 5155, ISO 5752, ANSI B16.10 |

| Ease of material selection | No galling is possible with this design making material selection simple |

| Sizes | 2” (50mm) to 84” (2100mm) |

| Pressure Ratings | ANSI 150# through 2500# |

| Torque | Under high pressure (14.5 Bar/210psi) the torque required to operate the valve was 160 N.M |

| Seal Temperature | During test burn period, where temperatures reached 1652°F (900°C) the high integrity metal/metal seal still ensured tight shut off |

| Bearing Protector | Enables arduous duty applications where solids may be present in the flow media. |

| Live Loaded Packing | A set of Belleville spring washers fitted to the gland follower provides automatic adjustment to packing. |

| Steam Jacket | integral steam jackets are available on the double flanged body design |

| Lantern Ring | Available for the packing box |

| Ease of actuation | Rotary action of the valve enables ease of actuation and suitability for either control or isolation |

| Superior gland performance | Rotary motion valves greatly reduced fugitive emissions from gland packing. In addition gland packing life is considerably improved |