As safety and environmental issues have become of greater concern to mankind, the need for assured valve shut off providing absolute and verifiable isolation are regularly becoming the standard specification for critical applications.

Typical areas of application include offshore and onshore petrochemical production including, gas injection, water injection, oil and gas transmission lines including airport fuelling facilities and other areas where flammable and toxic emissions are unacceptable.

Design Previous common practice has been to use two valves (Fig 1), such as plug or ball valve designs, in series with a bleed facility located between them in order to establish the sealing integrity of the upstream valve. This configuration is far from optimum as more space is required, with considerable extra weight quite apart from the additional maintenance requirements of having two valves and the extra associated costs.

Design Previous common practice has been to use two valves (Fig 1), such as plug or ball valve designs, in series with a bleed facility located between them in order to establish the sealing integrity of the upstream valve. This configuration is far from optimum as more space is required, with considerable extra weight quite apart from the additional maintenance requirements of having two valves and the extra associated costs.

The Solent & Pratt Double Block and Bleed design (Fig 3) utilizes our well established, Triple Offset segment valve (TOSV). This compact Double Block and Bleed Design negates the need for using two valves in series.

| Feature | Description |

| Shut Off | Shut off class API 598. Zero leakage shut off available in both directions |

| Seat and Seal | Replaceable body seats and laminated disc seals |

| Type | Triple Offset design (non-rubbing) |

| Materials | Materials of construction available to NACE requirements |

| Quality Assurance | Quality Assurance Systems approved to ISO 9001 |

| Non-rubbing design | The Triple Offset Geometry of the TOSV range eliminates all rubbing between seat and seal thus extending the performance and life expectancy of the valve |

| Body design | Double Flanged to ANSI B16. |

| Pressure Range | Size range 6” (150mm) to 84” (2100mm) ANSI 150#, 30# & 600#. Size range 6” (150mm) to 36” (900mm) ANSI 900# & 1500#. Larger sizes on request. |

| Firesafe | Inherently Firesafe primary metal/metal sealing certified to API 607 |

| Anti-Blowout | Internal anti-blowout stem standard. External to API 609 optional. |

| Flange Standards | All flange standards can be accommodated including ANSI, API, MSS, BS, PN and ISO. |

| ANSI w/ Fully Rated Trims | ANSI 150#, 300#, 600#, 900# & 1500# |

| Face to face dimensions | Face to face dimensions shown are to BS.5155. Options include ANSI B16.10 and API 6D. Non-standard dimensions are available on request. |

| Operators | Valves can be supplied with manual, electric, pneumatic or hydraulic operators. Fail-safe systems for emergency operation are also available. |

| Materials | Carbon Steels, 316 S/S, Duplex & Super Duplex Stainless Steel. 6Mo Stainless Steels, Bronze, Monel, Hastelloy B & C, Titanium, Zirconium, Incoloy. |

| Options | Double flanged to ANSI B16.10 |

Patented Two direction valve geometry

Patented Two direction valve geometry

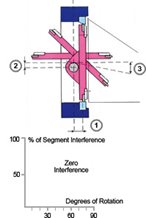

The Solent & Pratt Triple Offset Segment Valve utilizes the well established patented valve geometry where the shaft is offset from the body in two directions (1) and (2), whilst the disc is a segment taken from a cone where the apex is offset from the center line of the valve (3). The disc (segment) of the valve houses a field replaceable metal laminate seal whilst the field replaceable seat ring is housed in the body of the valve.

Due to the valve geometry there is no interference or rubbing between seat and seal as the valve strokes through it’s full 90°.